URGENT TAMPER-PROOF NUT TURNING

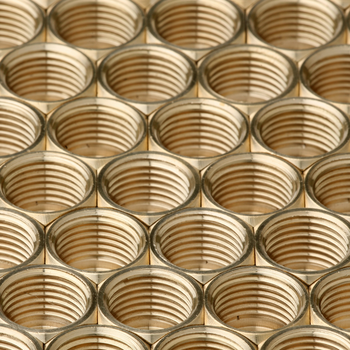

On the morning of October 10, we received a request from one of our customers, who produces gas ball valves in the province of Vicenza, to urgently produce a series of samples. Specifically, the request was associated with the production of turned brass tamper-proof nuts, to be made in four different sizes. The request was associated with customer's need to test new solutions for the safety of its products with nuts that were capable of breaking when subjected to a certain force, making it impossible to tamper with the valve. Given the urgency, we had to equip a Citizen L20 lathe with sliding headstock in the early afternoon, awaiting the arrival of the customer's technical department manager. As soon as the technician reached our facility, the workpiece turning process started, changing the slot diameter by a tenth of a millimetre four times. Immediately afterwards, the pieces were assembled on a valve and tested using a torque wrench. Once we had found the ideal size to produce the item, we delivered about 50 pieces to the customer. Within hours of the telephone call received by the Sales Department, thanks to the great responsiveness that has always made our turnery stand out, we were able to meet and resolve the urgent request, to the great satisfaction of the customer who, in turn, was able to solve its own issues and complete the deliveries. Thanks to this "urgent" sampling request, we now produce 10,000 nuts every month and we have signed additional sales contracts with the customer for the manufacture of all the machined samples processed with CNC lathes.